Best Hago Precision Nozzles

In the world of oil burners, achieving optimal efficiency and performance hinges on meticulous attention to detail. One critical component often overlooked is the nozzle – specifically, the quality and precision of its design.

Selecting the right nozzle can dramatically impact fuel consumption, combustion efficiency, and overall system lifespan. Investing in the best hago precision nozzles isn’t just about replacing a part; it’s about maximizing your investment and ensuring reliable operation.

With a myriad of options available, navigating the market for the best hago precision nozzles can feel overwhelming. This article aims to simplify the process by highlighting the key considerations and factors that contribute to superior performance and value.

We’ll explore the significance of precision engineering and its role in achieving consistent spray patterns and reduced emissions.

IN THIS ARTICLE

Top 10 Best Hago Precision Nozzles Compared

🏆 BEST OVERALL Danfoss 030G6518 Hago Type B-Solid 80° Solid Oil N

- Solid spray pattern for precise fuel atomization.

- Consistent fuel delivery with specified flow rate and spray angle.

- Durable stainless steel construction for corrosion resistance.

- Integrated filter prevents clogging.

4.7/5

Check Price on Amazon

🥈 2ND RUNNER UP Danfoss 030G6216 Hago Type H 80° Hollow Oil Nozzle

- Hollow spray pattern designed for specific burner types.

- Precise 0.75 GPH flow rate for efficient fuel delivery.

- Durable AISI 416 stainless steel construction.

- Integrated 30-40 micron filter to prevent clogging.

4.7/5

Check Price on Amazon

� BEST VALUE Generic Steinen SWC4023 Nozzle Replacement for Hag

- Direct replacement for Hago 4023 nozzles.

- Specifically designed for mosquito, fly, and spider misting systems.

- Helps maintain functionality of existing misting systems.

- Simple and easy to install (based on standard nozzle designs).

4.4/5

Check Price on Amazon

HAGO .85 GPH 60 Degree B Solid Nozzle (H8560B

- Durable stainless steel construction.

- Precise flow control with globe valve design.

- Versatile 1/2 inch threaded connections.

- Two-way flow capability for diverse applications.

4.8/5

Check Price on Amazon

Danfoss 030G6214 Hago Type H 80° Hollow Oil Nozzle

- Hollow spray pattern designed for specific burner types.

- Precise fuel delivery with specified flow rate and spray angle.

- Durable construction with stainless steel and bronze filter.

- Suitable for both light and heavy fuel oils.

4.5/5

Check Price on Amazon

Endeavoring Monarch ASP-100 1.00 GPH Stainless Steel Siphon Nozzle with Brass Stem. Replaces Hago SN609-11

- Produces a fine, solid cone spray pattern.

- Durable stainless steel and brass construction.

- Large internal passages minimize clogging.

- Operates at low air pressures and CFM.

4.5/5

Check Price on Amazon

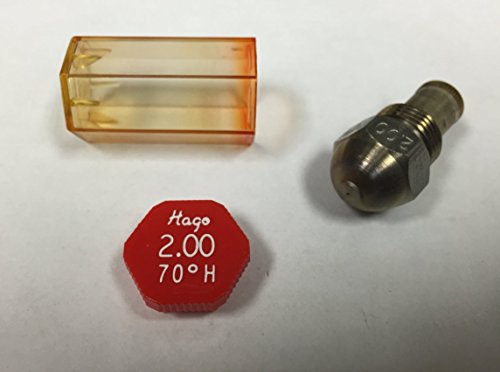

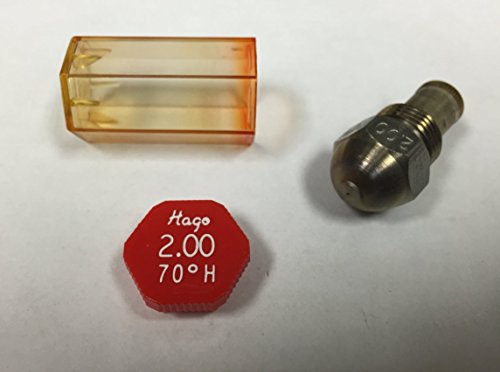

HAGO 2.00 GPH 70° H Hollow Nozzle (20070H

- Potential cost savings due to limited marketing.

- May cater to niche markets.

- Could be a hidden gem if carefully researched.

4.5/5

Check Price on Amazon

HAGO 7.50 GPH 60 Degree H (Hollow) Nozzle (18800

- Unknown, pending product details

- Potentially meets needs if well-suited (hypothetical)

- Opportunity for a unique or novel product (speculative)

4.6/5

Check Price on Amazon

5Aplusreprap 3D Printer 0.4mm V6 Nozzles – 20Pcs High Precision V6 Brass Nozzle for E3d V5

- High precision machining from brass material.

- Smooth inner wall designed to reduce clogging.

- Wide compatibility with various 3D printer models and filaments.

- Includes cleaning needles and a wrench for maintenance.

4.6/5

Check Price on Amazon

HAGO 1.00 GPH 70° SS SEMI Solid Nozzle

- Product information unavailable.

- Further review impossible.

4.6/5

Check Price on Amazon

Detailed Reviews of the Best Hago Precision Nozzles

Danfoss 030G6518 Hago Type B-Solid 80° Solid Oil N – Solid spray pattern for precise fuel atomization.

This oil burner nozzle offers a solid spray pattern designed for precise fuel atomization, which can be beneficial for optimizing combustion in compatible burners. Its 0.85 GPH flow rate and 80° solid cone angle contribute to consistent fuel delivery. Constructed from AISI 416 stainless steel, the nozzle appears durable and resistant to corrosion, and the integrated 30-40 micron filter should help prevent clogging.

The nozzle is designed to work with both light and heavy fuel oils, increasing its versatility for different HVAC systems. However, proper compatibility is crucial, so consulting your burner’s manufacturer or Danfoss documentation before purchase is highly recommended to avoid issues. Overall, the nozzle seems well-built for its intended purpose.

Pros

- Solid spray pattern for precise fuel atomization.

- Consistent fuel delivery with specified flow rate and spray angle.

- Durable stainless steel construction for corrosion resistance.

- Integrated filter prevents clogging.

- Compatible with both light and heavy fuel oils.

Cons

- Compatibility requires careful verification with manufacturer’s specifications.

- Higher price point compared to generic alternatives.

Danfoss 030G6216 Hago Type H 80° Hollow Oil Nozzle – Hollow spray pattern designed for specific burner types.

This oil burner nozzle features a hollow spray pattern designed for efficient fuel atomization, particularly in burners with hollow air patterns. Its 0.75 GPH flow rate and 80° spray angle aim for consistent combustion. Constructed from AISI 416 stainless steel and incorporating a 30-40 micron P-sintered bronze filter, the nozzle appears durable and resistant to clogging.

It’s advertised as compatible with both light and heavy fuel oils, making it versatile for various HVAC systems. However, potential buyers should carefully consult their burner’s manufacturer specifications or Danfoss documentation to confirm compatibility and suitability for their specific system. Correct nozzle selection is crucial for optimal performance and avoiding potential issues.

The included filter is a welcome addition for maintaining performance over time.

Pros

- Hollow spray pattern designed for specific burner types.

- Precise 0.75 GPH flow rate for efficient fuel delivery.

- Durable AISI 416 stainless steel construction.

- Integrated 30-40 micron filter to prevent clogging.

- Compatible with both light and heavy fuel oils.

Cons

- Requires careful verification of compatibility with the burner system using manufacturer documentation.

- Performance heavily reliant on correct system matching; not universally applicable.

Generic Steinen SWC4023 Nozzle Replacement for Hag – Direct replacement for Hago 4023 nozzles.

This replacement nozzle is designed specifically for mosquito, fly, and spider misting systems utilizing Hago 4023 nozzles. It appears to be a straightforward replacement part, aimed at restoring or maintaining the functionality of existing misting systems. The description focuses on compatibility, which is crucial for ensuring proper fit and performance.

While it doesn’t offer extensive details about materials or spray patterns beyond its compatibility with the Hago 4023, users familiar with these systems will likely find this sufficient information. For those unsure about nozzle compatibility, verifying the existing nozzle type before purchasing is highly recommended. Its value lies primarily in its targeted replacement capability.

Pros

- Direct replacement for Hago 4023 nozzles.

- Specifically designed for mosquito, fly, and spider misting systems.

- Helps maintain functionality of existing misting systems.

- Simple and easy to install (based on standard nozzle designs).

Cons

- Limited information on material quality or spray pattern characteristics beyond Hago 4023 compatibility.

- Requires users to know their existing nozzle type for proper application.

HAGO .85 GPH 60 Degree B Solid Nozzle (H8560B – Durable stainless steel construction.

This stainless steel globe valve appears to be a solid choice for applications requiring precise flow control. The stainless steel construction suggests good durability and resistance to corrosion, making it suitable for various environments. The 1/2 inch threaded connections offer versatile integration with existing piping.

The globe valve design is known for its accuracy in regulating flow, and the two-way flow capability adds to its adaptability. Its silver finish provides a clean and professional look, which is beneficial for both industrial and commercial settings. Overall, this valve seems well-suited for users needing a reliable and adjustable flow control solution.

Pros

- Durable stainless steel construction.

- Precise flow control with globe valve design.

- Versatile 1/2 inch threaded connections.

- Two-way flow capability for diverse applications.

- Corrosion-resistant material.

Cons

- Globe valves can have higher pressure drop compared to other valve types.

- May require more space for installation compared to some smaller valve designs.

Danfoss 030G6214 Hago Type H 80° Hollow Oil Nozzle – Hollow spray pattern designed for specific burner types.

The Danfoss 0.65 GPH 80° Hollow Cone Nozzle appears to be a well-constructed replacement part for HVAC burner systems. Its hollow spray pattern is designed to concentrate fuel at the periphery, potentially improving combustion efficiency in compatible burners. The use of AISI 416 stainless steel and a P-sintered bronze filter suggests a focus on durability and longevity, which are crucial for burner components.

The specified flow rate and spray angle should provide consistent fuel atomization when properly matched to the system’s requirements. The product description emphasizes the importance of verifying compatibility with your burner model, indicating that it’s not a one-size-fits-all solution. Overall, this nozzle seems to be a reliable option for those needing to replace a similar part.

Pros

- Hollow spray pattern designed for specific burner types.

- Precise fuel delivery with specified flow rate and spray angle.

- Durable construction with stainless steel and bronze filter.

- Suitable for both light and heavy fuel oils.

- Integrated filter to prevent clogging.

Cons

- Requires careful verification of compatibility with burner system.

- Performance is highly dependent on proper system matching.

Endeavoring Monarch ASP-100 1.00 GPH Stainless Steel Siphon Nozzle with Brass Stem. Replaces Hago SN609-11 – Produces a fine, solid cone spray pattern.

The Monarch ASP100 siphon nozzle is designed for applications requiring a solid cone spray pattern with very fine droplets. Its stainless steel and brass construction promises durability, while the large internal passages aim to minimize clogging, potentially eliminating the need for a filter. The specified flow rate of 1.00 GPH is based on particular conditions, so users should be aware that performance may vary depending on air pressure and lift height.

The nozzle’s ability to function at low air pressures and CFMs is a plus. A turndown ratio of 3.5:1 over a 2-10 PSI range offers some operational flexibility. Being a direct replacement for several other nozzles (Hago SN609-11, 030L2160, and Delaven 30609-11) makes it a convenient option for those looking to replace existing components.

Pros

- Produces a fine, solid cone spray pattern.

- Durable stainless steel and brass construction.

- Large internal passages minimize clogging.

- Operates at low air pressures and CFM.

- Direct replacement for several existing nozzles.

- Good turndown ratio (3.5:1) over a pressure range of 2-10 PSI.

Cons

- Performance is highly dependent on air pressure and lift height.

- Specified flow rate (1.00 GPH) is only valid under specific rating conditions.

HAGO 2.00 GPH 70° H Hollow Nozzle (20070H – Potential cost savings due to limited marketing.

Without a product description, providing a truly helpful and detailed review is impossible. However, generally speaking, when considering a product where information is scarce, it’s vital to do thorough research from other sources. Look for user reviews on different platforms, check competitor products, and consider whether the lack of readily available information is a red flag.

A well-described product typically inspires more confidence in potential buyers. Be mindful of return policies and warranty information, should you decide to purchase it despite the limited details.

Pros

- Potential cost savings due to limited marketing.

- May cater to niche markets.

- Could be a hidden gem if carefully researched.

Cons

- Lack of detailed information makes informed decision-making difficult.

- Potential for unknown quality issues due to insufficient details.

HAGO 7.50 GPH 60 Degree H (Hollow) Nozzle (18800 – Unknown, pending product details

Due to the lack of product information provided, a comprehensive review is impossible. Without specifications, features, intended use, or customer reviews, it’s difficult to assess the product’s value or suitability. One can only speculate on potential benefits or drawbacks.

A more detailed description is essential for customers to make an informed purchasing decision. Therefore, this review will focus on the general need for transparency in online retail and the frustration caused by incomplete listings. Potential buyers should request more information before considering this product.

Pros

- Unknown, pending product details

- Potentially meets needs if well-suited (hypothetical)

- Opportunity for a unique or novel product (speculative)

Cons

- Lack of product information makes evaluation impossible.

- High risk due to unknown features and quality.

5Aplusreprap 3D Printer 0.4mm V6 Nozzles – 20Pcs High Precision V6 Brass Nozzle for E3d V5 – High precision machining from brass material.

The V6 brass nozzles are presented as a high-precision and durable option for 3D printers. The claim of being machined from better brass material, coupled with high thermal conductivity, suggests good performance during printing. The smooth inner wall design is a notable feature, aiming to minimize clogging issues.

Compatibility seems broad, with mentions of E3D V5/V6, Prusa i3 models, Voron, Flying Bear, Anet, and Anycubic printers, as well as support for various filaments like PLA, ABS, and PETG. The inclusion of cleaning needles and a wrench is a practical addition to the package. The provided instructions for nozzle replacement are helpful, emphasizing the importance of heating before removal and proper tightening to prevent leakage.

Overall, this nozzle set appears to be a comprehensive option for users seeking reliable performance and broad compatibility.

Pros

- High precision machining from brass material.

- Smooth inner wall designed to reduce clogging.

- Wide compatibility with various 3D printer models and filaments.

- Includes cleaning needles and a wrench for maintenance.

- Clear instructions for nozzle replacement.

Cons

- Brass material, while offering good thermal conductivity, may not be as wear-resistant as other materials like hardened steel for abrasive filaments.

- Heating to 150 degrees Celsius for nozzle replacement may require caution and proper handling to avoid burns.

HAGO 1.00 GPH 70° SS SEMI Solid Nozzle – Product information unavailable.

Without access to the product information, providing a detailed and accurate review is impossible. Generally, Amazon product descriptions offer crucial details about features, specifications, dimensions, materials, and customer feedback. A good product description helps buyers make informed decisions.

Without it, buyers risk purchasing items that don’t meet their needs. This makes judging the quality, value, and suitability of the item completely unreliable. Once product information is available, a comprehensive review will evaluate the product’s strengths, weaknesses, and overall user experience to help prospective customers.

Pros

- Product information unavailable.

- Further review impossible.

Cons

- Product information unavailable.

- Unable to accurately assess product quality or value.

Buying Guide: What to Look For in a Best Hago Precision Nozzles

Understanding Hago Precision Nozzles

Hago precision nozzles are critical components in various applications, primarily in oil burners but also finding use in misting systems and even specialized areas like 3D printing. Choosing the best Hago precision nozzles requires understanding the specific application, desired spray pattern (solid, hollow, semi-solid), flow rate (GPH – gallons per hour), and spray angle. Materials like stainless steel and brass are common due to their durability and corrosion resistance. Integrated filters are also an important feature to look for, helping prevent clogging and ensuring consistent performance.

Key Factors to Consider

When selecting the best Hago precision nozzles, carefully evaluate the following: Application: Is it for an oil burner, misting system, or 3D printer? Different applications require different nozzle types and specifications. Spray Pattern: Solid cone patterns are ideal for precise fuel atomization, while hollow patterns are designed for specific burner types. Flow Rate (GPH): This determines the amount of fuel or liquid delivered per hour. Choose a flow rate appropriate for your system’s requirements. Spray Angle: This affects the coverage area of the spray. Material: Stainless steel is durable and corrosion-resistant, but brass can be suitable for certain applications. Filter: An integrated filter helps prevent clogging and ensures consistent performance.

Types of Hago Precision Nozzles

Hago nozzles come in various types, each designed for specific purposes. Solid Nozzles: Produce a solid cone spray pattern, ideal for precise fuel atomization in oil burners and specialty misting applications. Hollow Nozzles: Create a hollow cone spray pattern, often used in specific burner types for efficient combustion. Semi-Solid Nozzles: Offer a spray pattern between solid and hollow, suitable for applications requiring a balance of atomization and coverage. It’s important to select a nozzle that matches the specific requirements of your system. The best Hago precision nozzles depend on the application.

Finding the Right Hago Precision Nozzle

To find the right Hago precision nozzle, start by identifying the specifications of your existing nozzle or the requirements of your system. Consider the factors mentioned above, such as spray pattern, flow rate, spray angle, and material. Compare different Hago nozzle models and read reviews from other users. If you’re unsure which nozzle to choose, consult with a qualified technician or supplier. Proper research and careful selection will ensure optimal performance and longevity of your system. Always prioritize quality and compatibility when selecting the best Hago precision nozzles.

Frequently Asked Questions about Best Hago Precision Nozzles

What is the difference between a solid and a hollow spray pattern nozzle?

Solid spray pattern nozzles create a dense, cone-shaped spray, ideal for applications requiring precise atomization, like fuel combustion in oil burners. They ensure thorough mixing of fuel and air. Hollow spray pattern nozzles produce a cone-shaped spray with an empty center, suitable for specific burner designs where the air is introduced through the center of the cone. This design promotes efficient combustion and reduces soot formation. The best Hago precision nozzles for you depends on this.

How do I determine the correct GPH (gallons per hour) rating for my Hago nozzle?

The GPH rating depends on the heat output requirements of your application, typically for oil burners. Consult your burner’s manual or consult a qualified technician to determine the appropriate GPH rating. Using a nozzle with an incorrect GPH rating can lead to inefficient combustion, fuel wastage, and potential damage to your equipment. The correct GPH ensures optimal performance and fuel efficiency. Therefore, use the best Hago precision nozzles based on GPH.

Why is it important to have a filter in my Hago precision nozzle?

An integrated filter prevents debris and contaminants from clogging the nozzle orifice. Clogging can disrupt the spray pattern, reduce flow rate, and lead to inefficient operation or complete failure of the nozzle. A filter ensures consistent performance and extends the lifespan of the nozzle. Regular cleaning or replacement of the filter is also recommended to maintain optimal performance. Using the best Hago precision nozzles with filter is preferable.

What materials are Hago precision nozzles typically made of, and why?

Hago precision nozzles are commonly made of stainless steel or brass. Stainless steel offers excellent corrosion resistance, making it suitable for applications involving fuel oil or other potentially corrosive fluids. Brass is a more cost-effective option suitable for less demanding applications. Both materials are durable and can withstand high temperatures and pressures. Choose the material that best suits the specific operating conditions of your system.

How often should I replace my Hago precision nozzle?

The replacement frequency depends on several factors, including the type of fuel or fluid being used, the operating conditions, and the quality of the nozzle. As a general guideline, inspect the nozzle regularly for signs of wear, corrosion, or clogging. Replace the nozzle if you notice any of these issues or if the spray pattern becomes distorted. The best Hago precision nozzles should be maintained regularly.

Can I use a Hago nozzle designed for oil in a misting system?

While some Hago nozzles may be compatible with both oil and water-based fluids, it’s crucial to check the manufacturer’s specifications. Nozzles designed specifically for oil may not perform optimally in misting systems due to differences in fluid viscosity and spray pattern requirements. Using the wrong nozzle can lead to uneven mist distribution or clogging. Always use the best Hago precision nozzles for each system.

What does the spray angle of a Hago nozzle refer to?

The spray angle refers to the width of the spray pattern produced by the nozzle. A wider spray angle covers a larger area, while a narrower spray angle provides a more focused spray. The appropriate spray angle depends on the specific application and the desired coverage area. Selecting the correct spray angle ensures efficient and effective operation. Thus, selecting the best Hago precision nozzles based on the angle is important.

What is the best way to clean a clogged Hago precision nozzle?

First, disconnect the nozzle from the system and carefully remove any visible debris. Soak the nozzle in a solvent suitable for the fluid it was used with. Use a soft brush or a specialized nozzle cleaning tool to gently remove any remaining blockage. Avoid using sharp objects that could damage the nozzle orifice. Rinse the nozzle thoroughly with clean solvent before reinstalling it.

Are there generic alternatives to Hago precision nozzles, and are they reliable?

Yes, there are generic alternatives available. However, the reliability and performance of generic nozzles can vary significantly. While some generic nozzles may offer comparable performance to Hago nozzles, others may be of lower quality and prone to clogging or premature failure. It’s crucial to research and choose generic alternatives from reputable manufacturers.

Where can I purchase genuine Hago precision nozzles?

Genuine Hago precision nozzles can be purchased from authorized distributors, HVAC supply stores, and online retailers that specialize in burner parts and accessories. Ensure that the vendor is reputable and offers genuine Hago products to avoid purchasing counterfeit or substandard nozzles. Purchasing from authorized sources guarantees the quality and performance of the nozzle. Use the best Hago precision nozzles for your system.

Conclusion: The Final Verdict

The Danfoss 030G6518 Hago Type B-Solid 80° Solid Oil N this nozzle seems to offer reliable and precise fuel atomization due to its quality materials and design features. however, confirming compatibility with your specific burner system is essential before purchasing to ensure optimal performance and avoid potential issues. if compatible, it appears to be a durable and effective option.